Autoclaves and sterilizers are designed to be robust pieces of equipment, but if they have been idle for an extended period, restarting them may pose some challenges.

Here are some considerations:

Inspection and Maintenance:

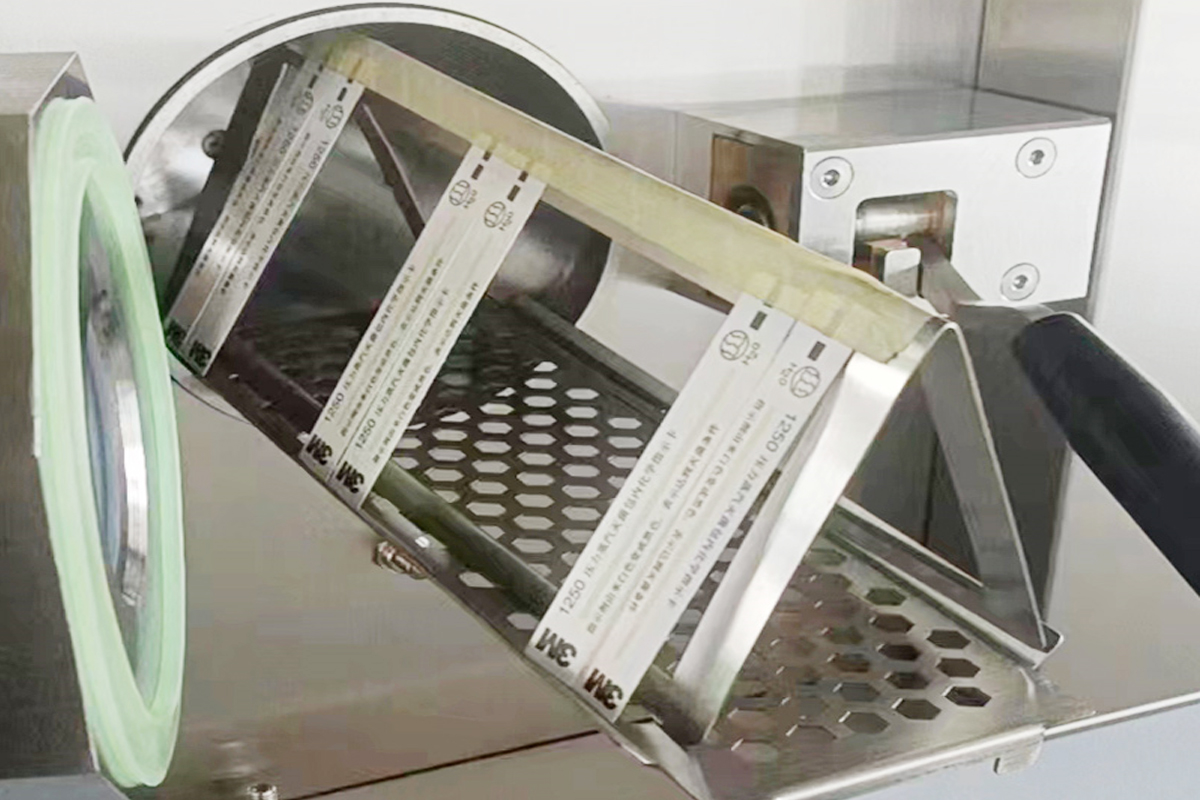

Before attempting to restart autoclaves and sterilizers that have been idle for an extended period, perform a thorough inspection. Check for any signs of damage, corrosion, or wear. Ensure that all components, including seals and gaskets, are in good condition.

Manufacturer's Guidelines:

Refer to the manufacturer's guidelines and user manuals for specific instructions on restarting the autoclave or sterilizer. The manufacturer's recommendations are crucial for ensuring proper operation and safety.

Calibration and Validation:

Calibrate the equipment according to the manufacturer's specifications. Additionally, validate the autoclave's performance to ensure that it meets the required sterilization standards. This may involve running test cycles with biological indicators and monitoring temperature, pressure, and other critical parameters.

Fluids and Lubrication:

Check and replace any fluids or lubricants that may have degraded over time. Lubricate moving parts as necessary to ensure smooth operation.

Electrical Components:

Inspect electrical components, such as wiring and control systems, for any signs of damage or wear. Ensure that the electrical connections are secure.

Training and Documentation:

Ensure that personnel responsible for operating the autoclave or sterilizer are trained on its proper use and maintenance. Update or review documentation, including standard operating procedures (SOPs), as needed.

Regulatory Compliance:

Ensure that the autoclave or sterilizer complies with any applicable regulations and standards. This may involve consulting with regulatory authorities or third-party certification organizations.

Run Test Cycles:

Before using the autoclave for actual sterilization purposes, run test cycles with load simulators or non-critical items to verify its functionality and to ensure that it achieves the required sterilization conditions.

Consult with Service Professionals:

If in doubt or if there are significant concerns, consider consulting with the equipment manufacturer or a qualified service professional for a thorough inspection and any necessary repairs.Restarting an autoclave or sterilizer after a prolonged period of inactivity requires careful attention to ensure safety, efficacy, and compliance with regulatory standards. Always follow the manufacturer's recommendations and guidelines, and consider seeking professional assistance if needed.